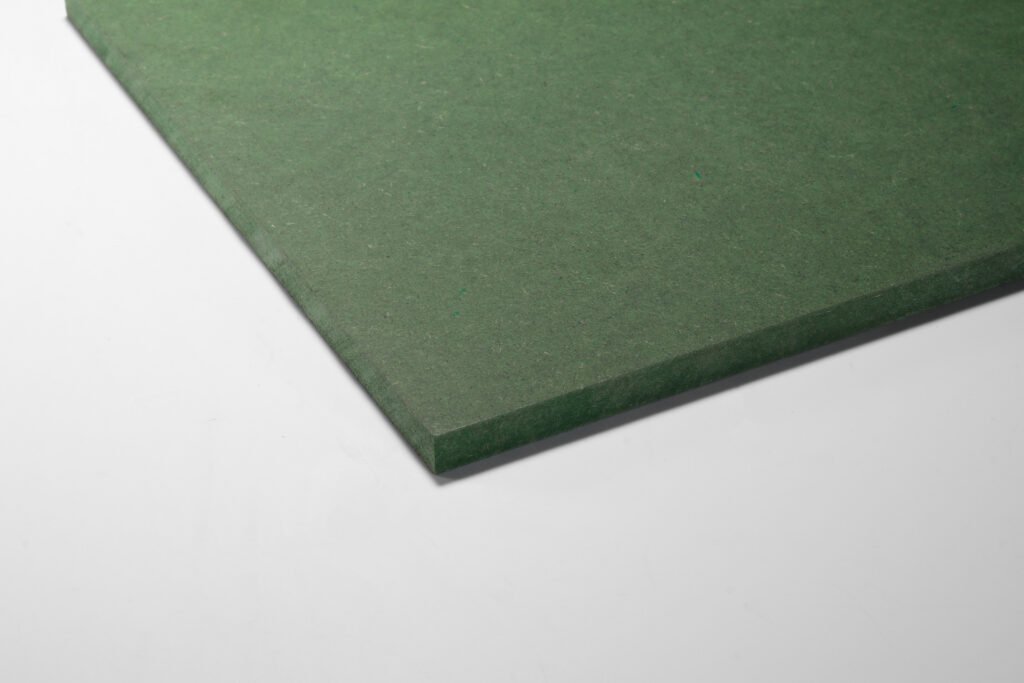

Painting MDF board the right way can transform affordable materials into sleek, professional-looking surfaces. Medium-Density Fiberboard (MDF) is a popular choice for furniture, shelving, cabinetry, and DIY projects because of its smooth surface and affordability — but it requires the proper prep and painting technique to ensure long-lasting results.

This complete guide will walk you through how to cut, seal, and paint MDF board correctly so you can achieve a flawless finish while avoiding common problems like swelling, paint blotching, or edge absorption.

1. Choosing the Right Tools for Cutting MDF

MDF can be challenging to cut cleanly due to its fine particle structure, which can lead to chipping and dust production. Using the right tools ensures smoother cuts and reduces wear on the material.

Tools You’ll Need:

- Carbide-Tipped Saw Blade: A fine-tooth carbide blade minimizes chipping and creates clean cuts. Circular saws, table saws, or jigsaws with fine blades are suitable for MDF.

- Dust Mask and Eye Protection: MDF produces a lot of fine dust when cut. Always wear a dust mask and eye protection, and consider cutting outdoors or in a well-ventilated area.

Tips for Cutting:

- Score the Cut Line: Use a utility knife to score along the cut line before making the actual cut. This reduces chipping along the edge.

- Slow and Steady: Move the saw blade slowly through the MDF to maintain a smooth cut. Rushing can cause the edges to chip.

- Support the Board: Use sawhorses or a stable surface to support the MDF while cutting. This prevents bending and helps you maintain a precise cut.

2. Sealing MDF Edges to Prevent Swelling

MDF is highly absorbent, especially at its edges, which can lead to swelling if exposed to moisture. Sealing these edges is essential for a long-lasting, professional finish.

Steps to Seal Edges:

- Apply a Water-Based or Oil-Based Primer: Brush a generous layer of primer onto all exposed edges. Water-based primer is often preferred for its quick drying time, but oil-based primer offers additional moisture resistance.

- Use a Sanding Sealer: Sanding sealers, often used for woodworking, can create a smoother, harder surface on MDF edges. Apply a thin layer with a brush and let it dry completely before sanding.

- Alternative Option – Wood Filler or Spackle: Spread wood filler or spackle along the edges, especially if you want an ultra-smooth finish. Sand it down once dry for a smooth, sealed edge.

Sanding After Sealing:

Once the primer or filler is dry, lightly sand the edges with fine-grit sandpaper (220-grit or higher) to smooth out any rough areas. This step ensures the edges are prepared for painting.

3. Priming MDF Surfaces Before Painting

Priming MDF is essential to prevent paint from soaking into the surface, which can lead to uneven color and texture.

Steps to Prime MDF:

- Select a Suitable Primer: Choose a high-quality water- or oil-based primer designed for wood surfaces. MDF primer is also available and specifically formulated for this material.

- Apply Even Coats: Use a foam roller or high-quality brush to apply the primer evenly on all visible surfaces, including edges. Applying two coats provides better coverage and protection.

- Allow to Dry and Sand: Let the primer dry fully between coats. After the second coat, lightly sand the surface with 220-grit sandpaper to remove any brush strokes or texture, resulting in a smooth surface for paint application.

4. Painting MDF for a Professional Finish

Choosing the right paint and technique will result in a polished, durable finish that can withstand wear and tear.

Steps to Paint MDF:

- Choose the Right Paint: High-quality latex or oil-based paints are ideal for MDF. Latex paint offers ease of use and quick drying, while oil-based paint provides a durable, hard-wearing finish.

- Apply Multiple Thin Coats: Instead of a single thick layer, apply multiple thin coats of paint using a foam roller for larger areas and a brush for edges. This technique ensures a smooth, even finish and reduces the risk of drips or streaks.

- Light Sanding Between Coats: Lightly sand between coats using fine-grit sandpaper. This process helps each coat adhere better and creates a flawless surface for the final coat.

- Finish with a Clear Coat (Optional): For projects that will experience heavy use or moisture exposure, consider applying a clear polyurethane or acrylic sealant over the paint. This step adds extra protection and increases durability.

Extra Tips for Painting MDF Successfully

- Avoid Exposure to Excessive Moisture: Even after sealing, MDF is not fully waterproof. Avoid placing MDF furniture or cabinets in areas with high humidity unless you apply a waterproof topcoat.

- Use Proper Fasteners: MDF is dense and can split if nails or screws are inserted too close to the edges. Pre-drill pilot holes and use fine-thread screws to prevent splitting.

- Consider Edge Banding: For highly visible edges, apply edge banding to cover the raw edges of MDF. Edge banding is a pre-finished strip that adheres to the MDF edge, providing a smooth, professional look without the need for sealing and painting.

Why Tacon Wood Industry’s MDF Products Are the Right Choice

At Tacon Wood Industry, we provide high-quality MDF products that are ideal for a range of construction and DIY projects. With attention to durability and cost-effectiveness, our MDF boards offer a reliable foundation for furniture, cabinetry, and other interior projects. For more information or to place an order, contact us at taconsales86@gmail.com—we’re here to help you bring your next project to life with high-quality MDF solutions.

FAQs: Painting MDF Board

Do I need to prime MDF before painting?

Yes. MDF absorbs paint easily, so applying primer helps create a uniform, sealed surface and prevents blotchy finishes.

What paint is best for MDF boards?

Latex or oil-based paints both work. Latex is easier to use, but oil-based paint offers a tougher finish.

Can I paint MDF without sealing the edges?

You can, but the edges will absorb moisture and may swell or look fuzzy. Sealing is essential for a smooth, lasting finish.

How many coats of paint should I apply?

Usually two to three thin coats are ideal, with light sanding between each for best results.