Particle board is a cost-effective and versatile material used in furniture, cabinetry, and construction. However, its unfinished surface can appear dull and rough. With the right painting and finishing techniques, you can transform particle board into a sleek, high-end product that looks polished and professional. This guide will walk you through the steps to achieve a premium finish on particle board.

1. Why Paint and Finish Particle Board?

Painting and finishing particle board enhances both its aesthetic appeal and durability. A well-finished surface:

- Protects against moisture damage and warping.

- Improves scratch resistance and longevity.

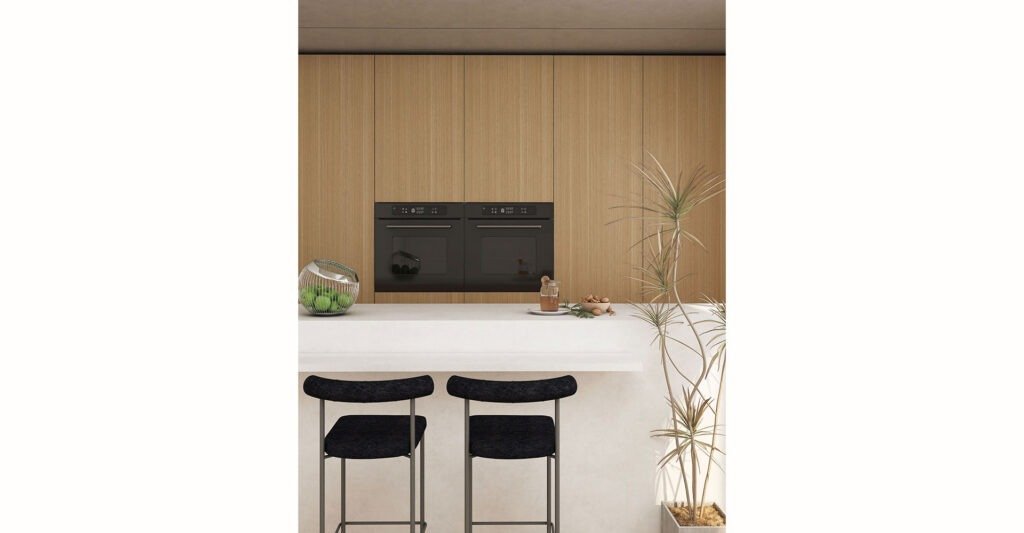

- Creates a smooth, visually appealing look that mimics solid wood.

- Allows for customization with different colors and textures.

Whether you’re working on furniture, cabinets, or decorative panels, painting and finishing particle board properly ensures a high-quality outcome.

2. Preparing Particle Board for Painting

Proper preparation is key to achieving a smooth, professional-looking finish. Follow these steps before applying paint:

Step 1: Clean the Surface

Dust, grease, and dirt can interfere with paint adhesion. Wipe the surface with a damp cloth and allow it to dry completely.

Step 2: Sand the Surface

Particle board has a rough, porous surface, so sanding is essential:

- Use medium-grit sandpaper (120-150 grit) to smooth the surface and edges.

- If the board has a laminated finish, lightly sand it with 220-grit sandpaper to create a surface that the paint can adhere to.

- Wipe off sanding dust with a tack cloth or damp rag.

Step 3: Fill in Gaps and Imperfections

Particle board often has rough edges and small holes.

- Apply wood filler or spackle to smooth out imperfections.

- Let it dry completely before sanding again with fine-grit sandpaper (220-grit).

3. Choosing the Right Primer

Primer is crucial for ensuring better paint adhesion and a smooth finish. Since particle board is porous, it can absorb paint unevenly, leading to blotchy results.

- Use a high-quality oil-based or shellac-based primer to seal the surface.

- Avoid water-based primers, as they may cause swelling.

- Apply one or two coats, allowing each coat to dry completely before sanding lightly with fine-grit sandpaper.

4. Selecting the Best Paint for Particle Board

The choice of paint affects both the appearance and durability of the finished product.

- Oil-based or enamel paints: Provide a durable and smooth finish, ideal for furniture.

- Acrylic latex paints: Offer a wide range of colors and are easier to clean but may require a protective topcoat.

- Spray paint: Ideal for a smooth, even coat but requires multiple layers.

5. Painting Particle Board for a Premium Finish

Step 1: Apply the First Coat of Paint

- Use a high-quality brush, roller, or spray gun for even coverage.

- Apply thin, even layers to avoid drips and streaks.

- Allow the first coat to dry completely before lightly sanding with fine-grit sandpaper (220-grit).

Step 2: Apply Additional Coats

- Depending on the type of paint and the desired finish, apply 2-3 coats.

- Sand lightly between coats for a flawless, smooth surface.

6. Sealing and Finishing for Long-Lasting Results

To protect the painted surface and enhance its durability, apply a topcoat or sealer:

- Polyurethane or Polycrylic Finish: Adds a protective layer and is available in glossy, satin, or matte finishes.

- Clear Wax: Provides a soft, vintage look and works well for decorative pieces.

- Lacquer Finish: Offers a hard, durable coating for a high-end, glossy finish.

Use a foam brush or sprayer to apply the sealer in thin, even layers, allowing each coat to dry before applying the next.

7. Final Touches and Maintenance

- Allow the finished piece to cure completely before heavy use (typically 24-48 hours).

- Clean with a soft, damp cloth to maintain the surface.

- Avoid excessive exposure to moisture and heat to extend durability.

Conclusion

Painting and finishing particle board properly can elevate its appearance, making it look like a high-end material. With the right preparation, paint, and protective finishes, you can achieve a smooth, durable surface that lasts.

Choose Tacon Wood Industry for High-Quality Particle Board

At Tacon Wood Industry, we specialize in providing premium particle board for furniture, cabinetry, and construction applications. Our high-quality materials ensure superior durability and easy finishing.

For inquiries, contact us at taconsales86@gmail.com and let us help you find the perfect particle board for your project!