Choosing the right type of plywood for your project is essential for achieving the best results in terms of durability, finish, and functionality. With so many plywood types available, understanding the distinctions between them can help you make an informed choice that meets your needs. Whether you’re planning a home renovation, a furniture project, or a structural application, each plywood type offers unique benefits. Here’s a guide to the main types of plywood and tips on selecting the right one for your project.

1. Softwood Plywood: Ideal for Structural and Outdoor Use

Softwood plywood is typically made from layers of softwood, such as pine, fir, or cedar. It’s commonly used for construction and outdoor projects because of its durability and strength.

- Applications: Softwood plywood is ideal for building walls, roofing, subflooring, and other structural applications. It’s also widely used in creating outdoor furniture and sheds.

- Durability: This type of plywood is designed to withstand heavy loads, making it an excellent choice for construction work. For outdoor use, opt for pressure-treated or marine-grade softwood plywood to improve resistance to moisture.

- Common Thicknesses: Available in thicknesses from ¼ inch to ¾ inch, making it versatile for various structural needs.

2. Hardwood Plywood: Durable and Attractive for Interior Projects

Hardwood plywood is made from hardwood species like oak, maple, birch, and mahogany. Known for its smooth finish and strength, hardwood plywood is commonly used in fine furniture, cabinetry, and interior decor.

- Applications: This plywood type is perfect for furniture-making, cabinetry, paneling, and interior decorative elements where appearance is important.

- Strength and Appearance: Hardwood plywood has a smooth, polished surface that can be stained or painted for a refined look. It offers excellent stability and can hold nails and screws well, which is important for furniture that may bear weight.

- Common Thicknesses: Typically available in 1/8 to ¾ inches, depending on the project’s requirements.

3. Marine-Grade Plywood: Best Choice for Moisture-Prone Environments

Marine-grade plywood is specially designed to withstand moisture, making it the go-to choice for projects exposed to high humidity or direct water contact. Made with waterproof adhesive and high-quality wood veneers, this type of plywood resists rot and warping.

- Applications: Marine-grade plywood is ideal for boat-building, docks, bathrooms, kitchens, and outdoor applications where moisture is a concern.

- Water Resistance: This plywood undergoes rigorous waterproofing treatments and uses high-quality veneers, ensuring maximum durability and water resistance.

- Cost: It’s one of the more expensive types of plywood due to its treatment and high-quality materials, but the investment is worth it for moisture-prone areas.

4. Aircraft Plywood: Lightweight Yet Strong for High-Performance Uses

Aircraft plywood, also known as aviation plywood, is made from thin veneers of mahogany, birch, or other hardwoods. It’s engineered to be incredibly strong while maintaining a lightweight profile, making it popular in aircraft construction and high-performance applications.

- Applications: Aircraft plywood is used in aircraft manufacturing, as well as in musical instruments, model-building, and applications requiring a balance of strength and lightness.

- Durability: This plywood type is designed for high-stress situations and extreme environments, offering strength and flexibility without added weight.

- Availability: Aircraft plywood is more costly and may be harder to find, as it’s highly specialized.

5. Flexible Plywood: Great for Curved Surfaces and Unique Designs

Flexible plywood, or “bendy plywood,” is made with thin veneers that allow it to bend easily, making it ideal for curved applications. This type of plywood can be molded into arches, rounded furniture, and other unique designs.

- Applications: Flexible plywood is ideal for curved furniture designs, interior arches, wall paneling, and any project that requires bending.

- Ease of Use: While it’s thin and flexible, this plywood still provides reasonable durability for lightweight decorative or design elements.

- Thickness: Usually available in thinner sheets (3mm to 6mm), making it easy to shape without cracking or splitting.

6. Fire-Retardant Plywood: Essential for Fire-Sensitive Spaces

Fire-retardant plywood is treated with chemicals that slow down the spread of flames, making it suitable for spaces where fire resistance is a priority. This treatment allows the wood to meet building codes and regulations in fire-prone areas.

- Applications: Fire-retardant plywood is often used in commercial buildings, interior paneling, ceilings, and walls in areas with strict fire codes.

- Safety Benefits: By slowing down flame spread, this plywood provides added safety in case of fire and is a valuable choice for public buildings, offices, and other high-traffic areas.

- Availability: Fire-retardant plywood may cost more than standard options due to the fire treatment process, but it offers peace of mind in critical areas.

7. Decorative Plywood: Stylish Options for Visual Appeal

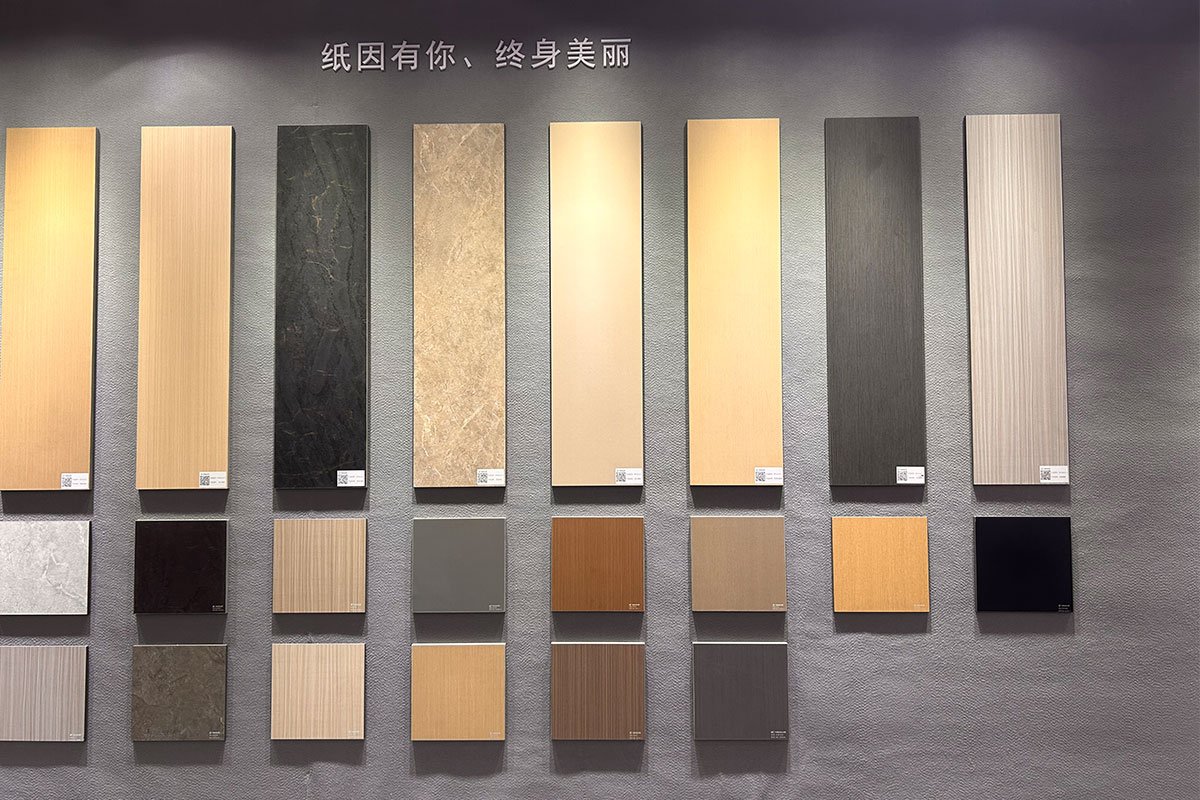

Decorative plywood is manufactured with a variety of finishes and textures, such as natural wood veneers, printed patterns, or high-gloss laminates. It is designed for aesthetic appeal and often used in home decor projects.

- Applications: Decorative plywood is perfect for wall paneling, interior decor, and custom furniture where appearance is key.

- Aesthetic Flexibility: This plywood can come in various veneers or be painted, stained, or laminated to suit any decor style.

- Thickness Options: Available in a range of thicknesses, decorative plywood can be chosen based on the desired finish and durability for your project.

Choosing the Right Plywood for Your Project

When selecting plywood, consider factors like the environment where it will be used, the load it needs to bear, and the visual aesthetic you want to achieve. Here are a few general tips to keep in mind:

- Outdoor vs. Indoor: For outdoor projects, opt for marine-grade or treated softwood plywood to ensure it withstands moisture and temperature changes.

- Weight-Bearing Needs: For heavy-duty furniture or structures, choose hardwood or thick softwood plywood. For lightweight projects, flexible or aircraft plywood may be better.

- Budget: While marine and hardwood plywoods tend to be pricier, they offer specific benefits. Decorative or flexible plywood can be cost-effective for light, non-structural applications.

- Appearance: If the plywood will be visible, go for hardwood or decorative options with attractive veneers that can be stained or painted.

Conclusion

Plywood offers unmatched versatility, strength, and design options, making it one of the most popular materials across industries. Whether you need waterproof options for outdoor furniture, fire-resistant materials for safe spaces, or flexible sheets for artistic designs, there’s a plywood type suited to your needs. At Tacon Wood Industry, we provide a wide range of high-quality plywood products for all applications. Reach out to us at taconsales86@gmail.com to learn more about our offerings and let us help you find the perfect plywood for your next project.