Particle board is a versatile and cost-effective engineered wood product widely used in furniture, cabinetry, and construction. Made from wood chips, sawdust, and resin, it is compressed into sheets to create a durable and smooth surface. With its affordability and adaptability, particle board has become a popular alternative to plywood and MDF in many applications.

How Is Particle Board Made?

The manufacturing process of particle board involves several steps:

- Wood Processing – Waste wood materials like sawdust and wood chips are collected.

- Drying & Sizing – The wood particles are dried and refined to a uniform size.

- Resin Application – The particles are mixed with a strong adhesive resin.

- Compression & Heat Treatment – The mixture is compressed under high pressure and heat to form sheets.

- Cutting & Finishing – The boards are cut into different sizes and finished with laminates or veneers.

Types of Particle Board

- Standard Particle Board – The most common type, used in furniture and interior applications.

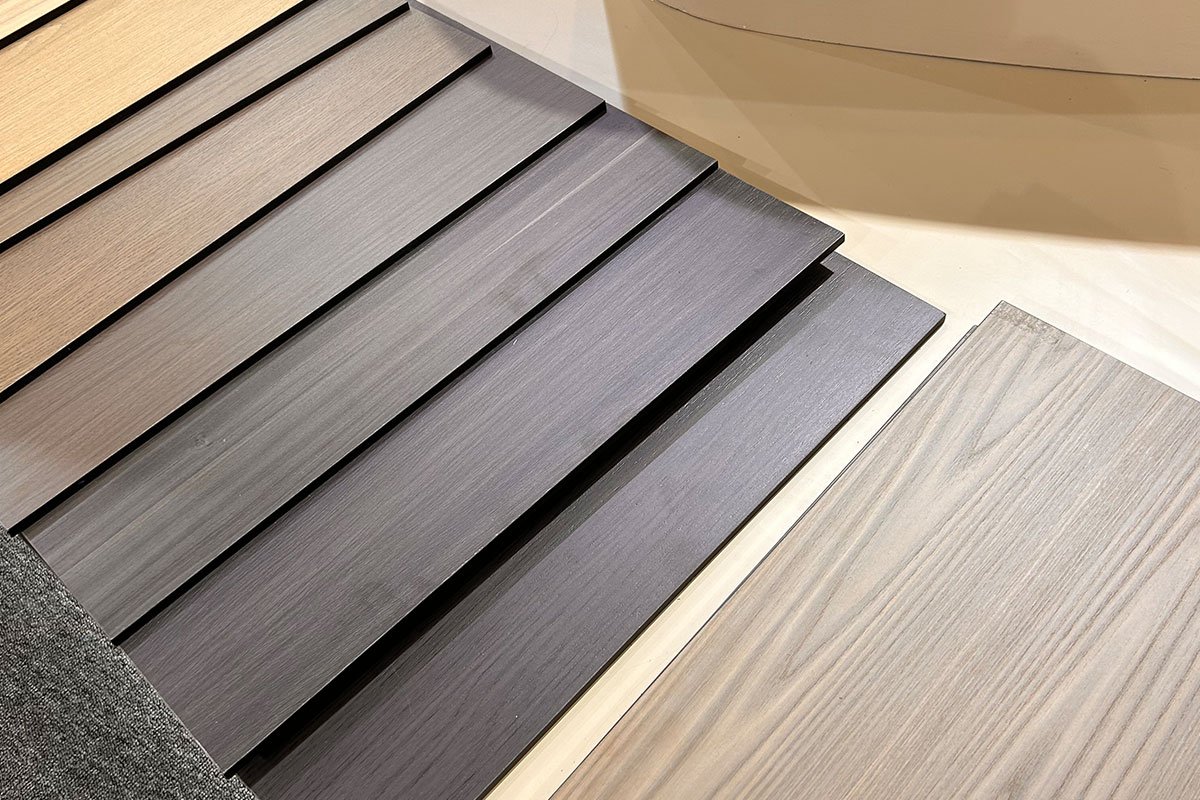

- Melamine Faced Particle Board – Covered with a decorative melamine layer for enhanced aesthetics.

- Laminated Particle Board – Features a laminate coating for increased durability and water resistance.

- Moisture-Resistant Particle Board – Specially treated for use in humid environments like kitchens and bathrooms.

- Fire-Retardant Particle Board – Infused with fire-resistant chemicals for added safety.

Advantages of Particle Board

✅ Affordable – Particle board is significantly cheaper than plywood and MDF.

✅ Eco-Friendly – It utilizes wood waste, making it a sustainable option.

✅ Smooth Surface – Ideal for laminates, veneers, and paint finishes.

✅ Lightweight – Easier to transport and handle compared to solid wood.

✅ Versatile Applications – Suitable for furniture, cabinetry, wall panels, and flooring.

Common Uses of Particle Board

- Furniture Manufacturing – Used in office desks, wardrobes, kitchen cabinets, and shelving units.

- Interior Decor – Applied in wall paneling, partitions, and ceiling panels.

- Flooring – Provides a smooth subfloor base under carpets and laminate flooring.

- Packaging Industry – Used for making crates and lightweight packing boxes.

Particle Board vs. MDF vs. Plywood

| Feature | Particle Board | MDF | Plywood |

|---|---|---|---|

| Cost | Low | Moderate | High |

| Strength | Moderate | Higher than PB | Strongest |

| Weight | Light | Heavy | Moderate |

| Moisture Resistance | Low (unless treated) | Moderate | High |

| Surface Smoothness | Smooth | Very Smooth | Rough |

| Best For | Furniture, shelves | Decorative panels, doors | Structural applications |

How to Maintain Particle Board

✔ Avoid Excess Moisture – Keep particle board away from direct water exposure.

✔ Use Protective Coatings – Apply laminate or veneer to extend its lifespan.

✔ Handle with Care – Prevent heavy impact to avoid chipping or cracking.

✔ Regular Cleaning – Wipe with a dry or slightly damp cloth to remove dust and stains.

Why Choose Tacon Wood Industry for Your Particle Board Needs?

At Tacon Wood Industry, we specialize in high-quality particle board for furniture, construction, and interior applications. Our affordable pricing, custom sizes, and eco-friendly solutions make us a trusted choice for global customers. Contact us today at taconsales86@gmail.com for more details or a free quote!