Particle board, also known as chipboard, has become a go-to material for furniture manufacturers worldwide. It’s affordable, versatile, and environmentally friendly, making it an attractive alternative to solid wood and plywood. But why exactly are more furniture manufacturers opting for particle board in their designs? Let’s explore the reasons behind this growing trend.

1. Cost-Effectiveness

One of the main reasons particle board is gaining popularity among furniture manufacturers is its affordability. Compared to solid wood or plywood, particle board is significantly cheaper to produce. The use of recycled wood materials and byproducts from other industries reduces the overall cost of raw materials, which in turn makes the final product more budget-friendly for both manufacturers and consumers.

By keeping production costs low, furniture manufacturers can offer stylish, functional pieces at a more accessible price point, making it an ideal option for mass-market furniture.

2. Versatility and Easy Customization

Particle board is highly versatile and can be customized to meet various design needs. It can be easily cut, shaped, and molded into complex forms, which allows furniture manufacturers to create intricate designs and functional pieces like shelving units, cabinets, and tables.

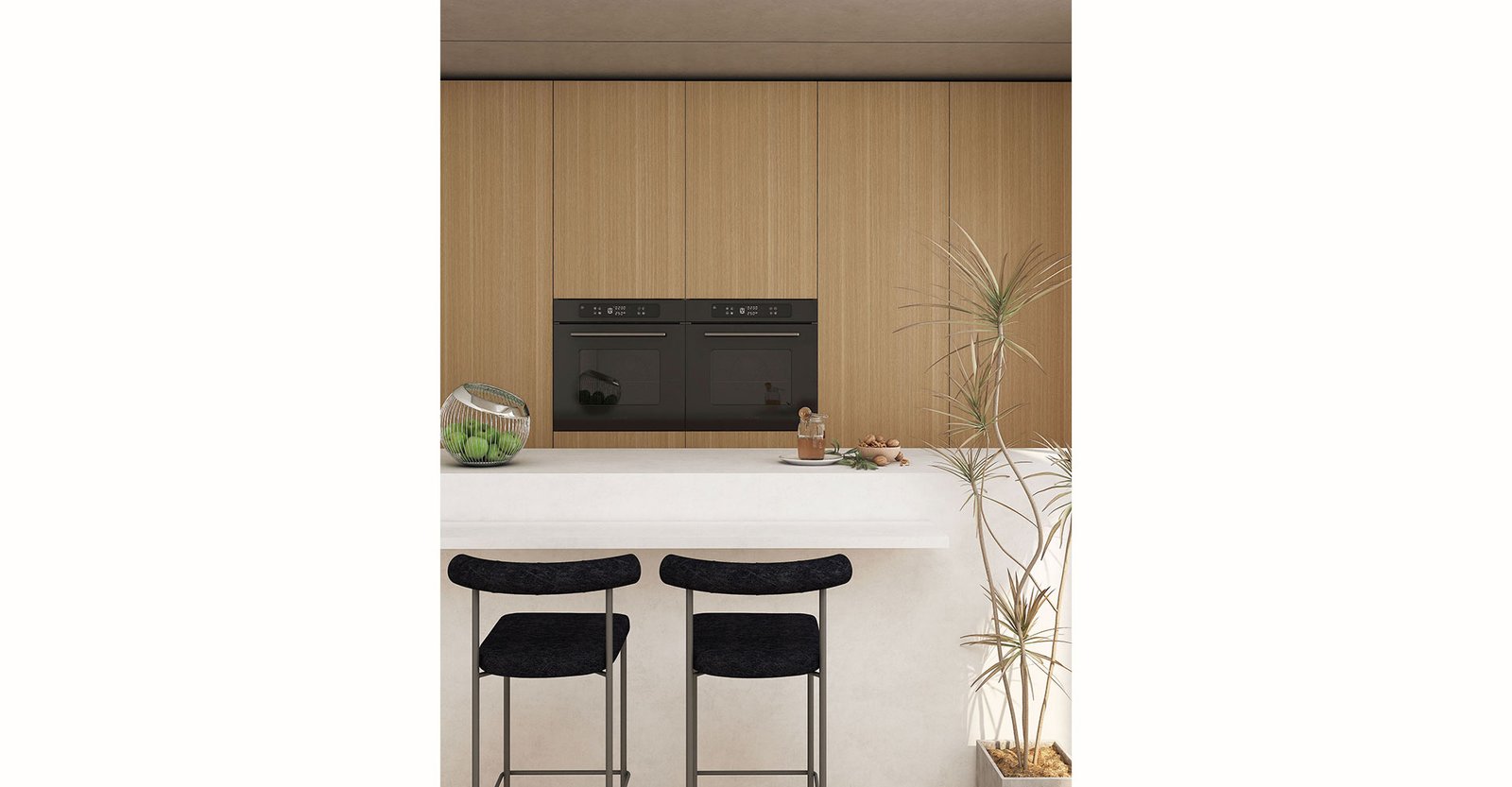

The material can also be easily laminated or veneered to mimic the appearance of solid wood or other high-end materials, offering aesthetic flexibility. Whether it’s a sleek modern design or a rustic look, particle board can be finished to match the desired style.

3. Lightweight and Easy to Handle

Compared to solid wood or plywood, particle board is relatively lightweight. This makes it easier for manufacturers to handle, transport, and assemble, reducing labor costs and improving efficiency in the production process. Additionally, furniture made from particle board is often easier for consumers to move and install in their homes.

4. Eco-Friendly and Sustainable

Sustainability is increasingly important to both consumers and manufacturers, and particle board offers a more environmentally friendly option than solid wood. Made from recycled wood scraps, sawdust, and other byproducts, particle board helps reduce waste and the demand for new timber.

Many manufacturers are also adopting low-formaldehyde or formaldehyde-free adhesives in particle board production to further reduce the environmental impact and meet stringent indoor air quality standards. This commitment to eco-friendly production is making particle board an attractive option for both manufacturers and consumers who prioritize sustainability.

5. Durability and Strength

While particle board may not be as strong as solid wood or plywood, advancements in manufacturing technology have improved its durability. High-density particle board is now widely available, offering greater strength and resistance to wear and tear. With the addition of moisture-resistant or fire-retardant coatings, particle board can be used in a variety of environments, from kitchens to office spaces, without compromising durability.

6. Easy to Work With and Cost-Effective Manufacturing

Particle board is easier to work with than solid wood due to its uniformity. Unlike solid wood, which can have knots, grain patterns, and inconsistencies, particle board has a consistent texture, making it simpler to cut and shape. This not only streamlines the manufacturing process but also reduces the time and effort required for finishing and assembly.

The use of particle board allows for faster production cycles, which is beneficial for furniture manufacturers aiming to meet consumer demand efficiently.

7. Availability and Supply Chain Efficiency

The availability of raw materials for particle board is another reason manufacturers are choosing it. Since particle board is made from waste wood products and recycled materials, the supply of these materials is typically more abundant and reliable than the sourcing of solid wood. This helps ensure a more stable and efficient supply chain for manufacturers.

8. Competitive Pricing

Because particle board is less expensive to produce, furniture manufacturers can offer products at a competitive price point while maintaining healthy profit margins. This is especially important in a market where consumers are increasingly looking for affordable yet stylish furniture. Manufacturers who choose particle board can compete with solid wood furniture options without sacrificing quality or aesthetics.

Choose Tacon Wood Industry for High-Quality Particle Board

At Tacon Wood Industry, we provide high-quality, durable, and eco-friendly particle board for furniture manufacturers. Whether you’re looking for a cost-effective solution, customization options, or a sustainable material, we have the perfect products for your needs.

For inquiries, contact us at taconsales86@gmail.com and let us help you create the best furniture with our superior particle board solutions!